F55CV Wood Burning Space Heater with Chimney Assist Fan

F55CV

VAT

| Dimensions | |

|---|---|

| Length | 1150 mm |

| Width | 700 mm |

| Height | 1550 mm |

| Depth | 1150 mm |

| Flue Spigot Internal Diameter | 180 mm |

| Fuel Chamber Depth | 660 mm |

| Fuel Chamber Width | 480 mm |

| Fuel Chamber Height | 600 mm |

| Min Clearance Side | 600 mm |

| Electrical Consumption | |

| Electrical Phase | Single phase |

| Ventilation Fan Power | 0.26 kW |

| Flue Fan Power | 0.26 kW |

| Ventilation | |

| Air Delivery Pipe Diameter ID | 200 mm |

| Number of Air Delivery Pipes | 2 |

| Ventilation Fan Power | 0.26 kW |

| Heated Air Flow | 3500 m3/hr |

| Fuel Type | |

| Fuel Type | Pallet Wood, Carpentry Waste, Approved Wood Waste, Wood log |

| Fuel Consumption | 20 Kg/hr |

| Chimney Specification | |

| Flue Spigot Internal Diameter | 180 mm |

| Flue Fan | yes |

| Flue Fan Power | 0.26 kW |

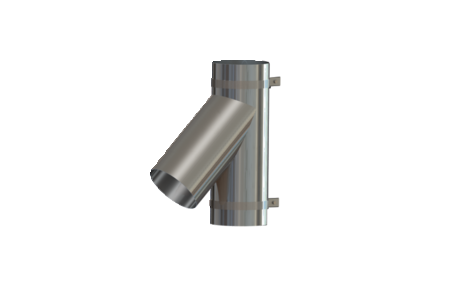

F55 CV with Flue fan

Medium-sized in the range of space heaters. It is ideal for areas that require quick heating or constant all-day heat requirements.

With its larger fuelling capacity than the F28 and the resultant higher heat output, the F55 is more suitable for larger workshops.

The footprint of the F55 is a little larger than the F28 but it will still only take up minimal space yet produce large amounts of heat in a short time.

The F55CV model comes with a chimney flue fan. This fan activates from the controller and produces a negative pressure within the flue. A chimney system is still required to expel the produces of combustion.

Wood fuel

Wood for burning in the space heater can come in many forms, the most important point is that it is dry. Small kindling will be needed to light the heater then large wood sections for continuous operation.

How to light your Zero space heater

It’s a very simple and very quick operation. Lay smaller kindling sized wood along with crumpled paper towards the front of the fuelling chamber. Open the open flap, light the paper and off you go.

The space heater has two front doors, the lower for access to remove ash whilst the upper door allows access for fuelling of the wood.

Automatic activation

The space heater includes a simple and easy to use control activation system. When the onboard temperature sensor detects heat in the upper chamber, it automatically starts the air distribution fans which bring in cold air from the bottom of the unit, heat this up, and then expels the warm air out of the distribution tubes at the top.

Directional air ducts

The directional exit air tubes allow the user to move the directions fast flowing heat air to where its most needed by a simple rotation.

Air volume

The onboard fan will move around 3500 m3/hr of air.

As a guide if the area to be heated is 1,000m3 of volume the air will pass through the space heater 3.5 times in 1 hour. So, the whole volume of that space will be reheated 3.5 times every hour.

Heat output control

The heater is fitted with two air control flaps, an upper (secondary air) flap and a lower (primary air) flap. The primary air flap is simply adjusted by turning a knob to increase or decrease the burning speed, while the upper secondary air control mixes air with the burning gasses to improve the burning efficiency.

Cleaning and maintenance

How often you will need to give the hot air heater a clean depends on the fuel used and quantity burnt. However, the system is designed to run for long periods between larger cleans smaller de-ashing can be as little as once per week.

Summer operation

As a very useful extra, the onboard fans can be activated in warm conditions to push cooling are around your workshop or factory.

Installation

Installation is very straight forward. Choose an allocated location for the wood space heater. If using the provided chimney installation kit, connect the flue together until it reaches the roof area. Mark and cut a suitable hole, continue the flue until it achieves the correct height. Fit the chimney roof support and flashing around the chimney and the chimney cowl if supplied. We would recommend an experienced installer to asset with the installation. Connect the electrical supply (details of power requirement are in the technical details).

Running costs

The on-board air circulation fan requires a small amount of electricity, (see technical table for details). No regular spare parts are expected if the boiler is maintained. Eventually, you may require a grate or other part, but this should be a long way in the future.

VAT

VAT

We use case studies as examples of how and where our solutions work best. We try and give an example of each model and an application or environmental improvements.