This heater can be fuelled with the waste scraps that are created when processing logs, effectively the sweepings off the floor and other malformed logs.

BCF Logs is a third generation log supplier based in south Herefordshire. Brian’s Grandfather started the business in the 1960s and his father took over in the 1980s, Brian then took over the reins six years ago in 2018. Over the years there have been many changes in technology used to process the logs, and the kiln dryer is the latest innovation to improve the process.

BCF Logs have always supplied quality seasoned, barn dried hardwood logs and have an ever growing customer base. In the past they have been able to cut and process enough logs to fill their large barn in the spring and let them season slowly all summer and by the autumn they would be dry and ready to deliver as the colder nights begin.

As demand has increased, partly due to the fuel crisis, they have found themselves having to cut and process logs in the autumn and winter and drying them has become more difficult as the weather over the last few years has been warmer an wetter than normal. Add to this the Government requirement since 2021 that all firewood sold commercially has to be “ready to burn” meaning it has to dry (20% moisture content).

With the new kiln setup they can cut and split the logs and store them in the barn to air dry for 2 months, before they are moved into the kiln for four or five days to finally reduce the moisture content down to the specified 20%.

The kiln setup up consists of a 20 foot ISO insulated container, that can hold 16 crates of logs, attached to this is a Fabbri F55 wood fuelled air heater. This heater can be fuelled with the waste scraps that are created when processing logs, effectively the sweepings off the floor and other malformed logs.

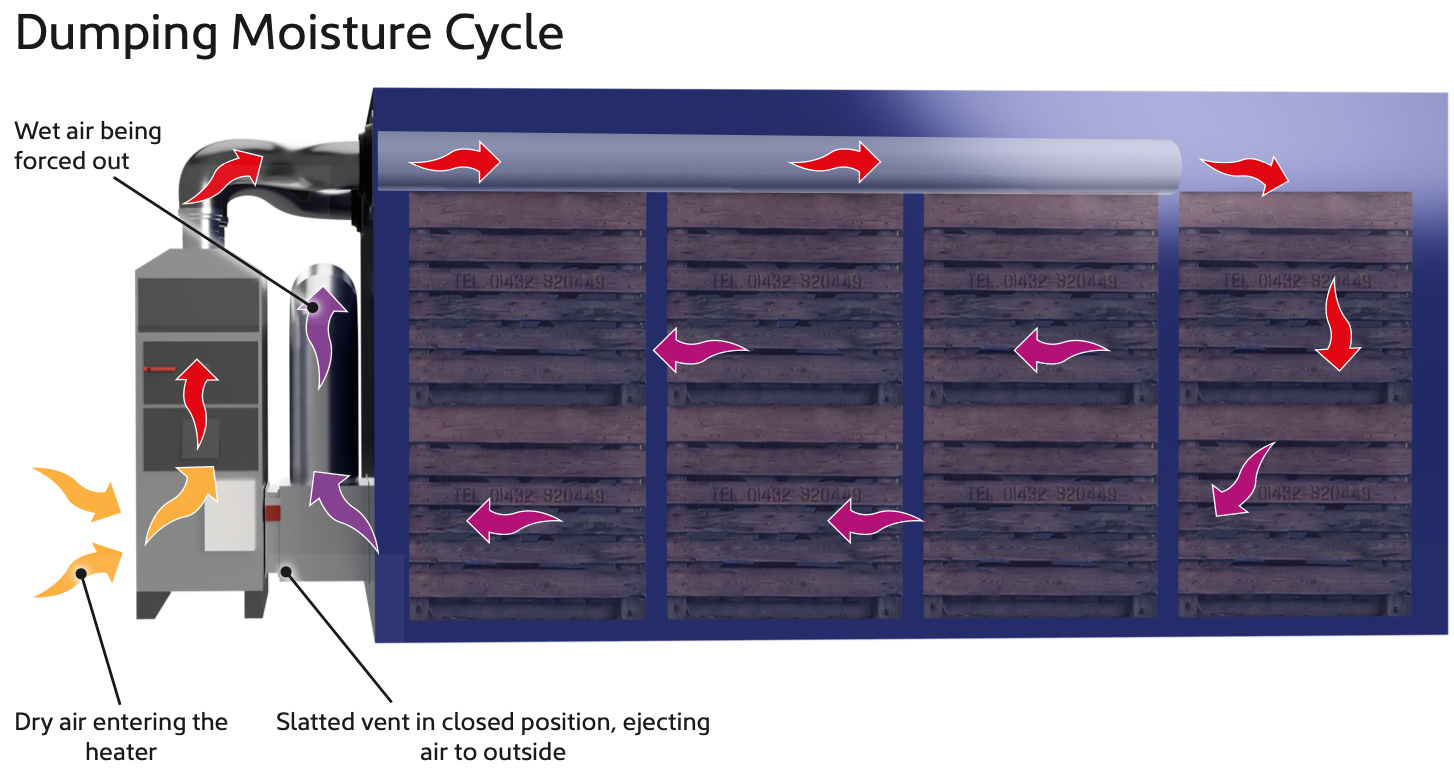

The drier can produce 3500 cubic metres of hot air an hour, meaning the air in the container is circulated within the closed system an impressive 93 times an hour. The moisture content of the air is monitored and when a specified saturation point is reached a vent opens and the wet air is dumped to the atmosphere, at the same time new drier air is sucked in to replace it, the sensors automatically sense the dry air and when the air in the container is dry enough the vent shuts and the sealed system heats the air again starting the drying cycle again.

On those cold, damp winter days, when natural drying conditions are poor, having the ability to quickly dry the logs to the desired amount is crucial and keeps the production line moving and provide more dry logs for contented customers.

How it works

The Wood Heater sucks air from inside the drying chamber, heats it and blows it into the top of the chamber.

Recirculation system

The heated air is blown into the drying chamber, circulated, then returned to the Zero Wood Heater creating a closed loop, reheating the air and forcing the temperature higher and higher.

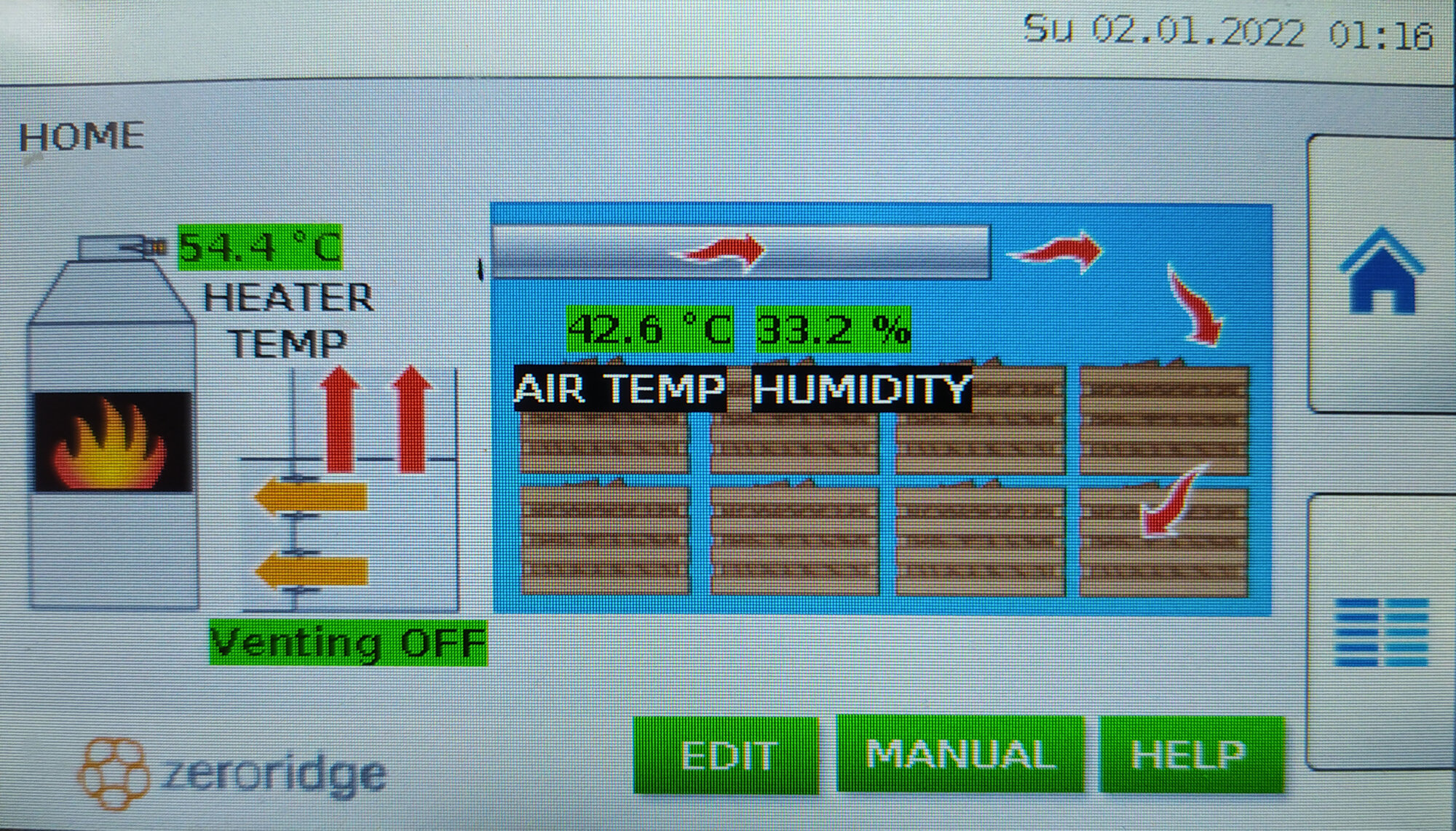

Automatic Control (Zero Kiln Control)

As air returns to the heater it is monitored for moisture content and when it reaches a given saturation point the wet air is redirected to outside of the container. The heater draws drier air from outside, when the sensor detects that the air in the container is dry enough it closes the vent and the air is circulated in a closed loop until it again reaches saturation point and the process starts again. The system also includes an overheat sensor so if system gets too hot the system dumps heat until back within set points.

This process of heating and venting the moisture at the optimum time makes the process as efficient as possible.

- The system comprises of a wood fuelled F55CV (64kW) hot air blower forcing air into an insulated, 20ft, ISO container which can accommodate 16 crates full of loose logs.