The Log Yard Hereford was struggling to keep up with demand during the cost of living crisis and added a kiln dryer to help speed up their drying process.

Since the UK Government introduced the "Ready to burn" scheme in England back in 2021, that legislated that all firewood been sold in less than 2 cubic metres has to be less than 20% moisture content, which prompted many fire wood producers to rethink their drying operations.

The Log Yard had always and still does, produce top quality, dry firewood, but with the increasing demand, driven by the fuel crisis, they were struggling to keep up and the natural log drying process needed a boost to keep things moving. So they installed a kiln drying system with a wood fuelled, hot air dryer, blowing air through a container. This is used at the end of their natural drying process after the logs have air dried, and is only used when necessary to keep the moisture content down to the legislated less than 20%.

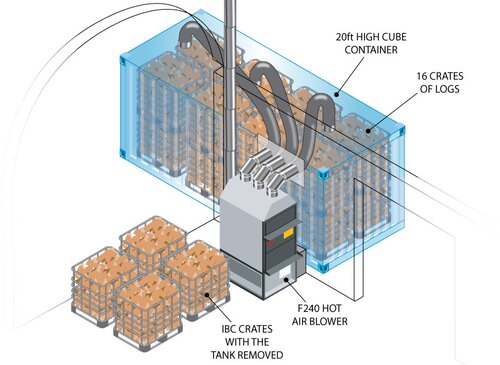

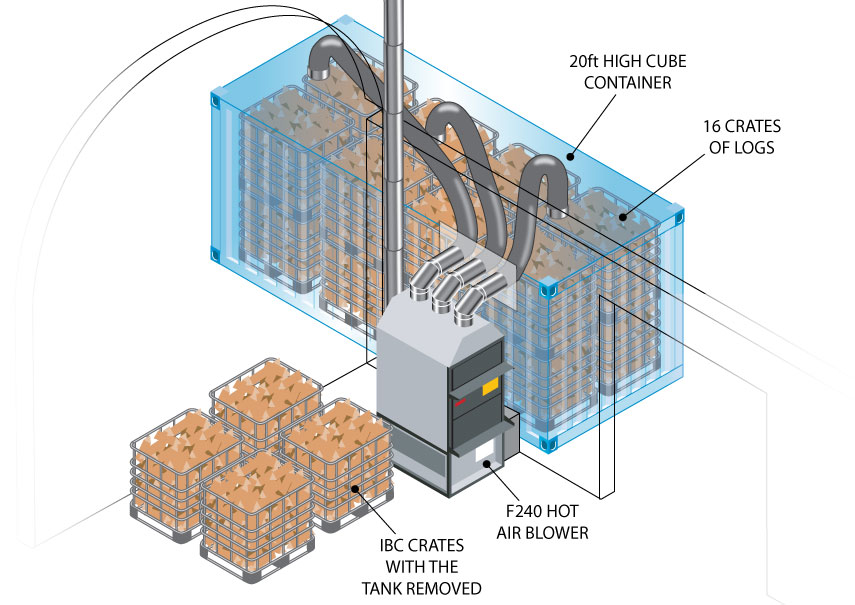

The system comprises of a wood fuelled F240 (279kW) hot air blower forcing air into an insulated, 20ft, high cube, ISO container which can accommodate 16 IBC crates full of loose logs (8 tonnes in total).

The heater is fuelled with wood waste from the log splitting process (basically the sweepings off the floor) which are air dried in paper potato bags, these bags (Simon calls them "bombs") are loaded straight into the firebox of the heater, this and any mis-shaped, gnarly logs that are not suitable for resale, provide the heat necessary to run the kiln dryer.

The blower can move 17,800 m3/hr and as a high cube 20ft container is only 37.4 m3 meaning the air is moved through the container an impressive 475.9 times an hour. Some of the air is vented outside whilst the majority is sucked back through the heater to be reheated and reused, as this air is still warm or hot, the container temperature steadily increases accelerating the drying process.

Sixteen crates of logs can be dried in as little as 24 hours if the kiln is running constantly but normally lighting the kiln at the start of the working day and letting go out at night means it takes two working days. The temperature and humidity within the kiln are constantly monitored and and the air flow can be directed as required by closing flaps on the exterior of the kiln and opening the return duct to the heater, which allows venting of the hot moist air.

Simon and Annie Bolt set up their kitchen cabinet making business back in 1980 and in recent years have slowly downsized focussing their efforts on restoring their farm buildings and processing firewood. They are passionate about providing a quality product at a fair price.

- The system comprises of a wood fuelled F240 (279kW) hot air blower forcing air into an insulated, 20ft, high cube, ISO container which can accommodate 16 IBC crates full of loose logs (8 tonnes in total).